Connect Your Operators and Digitalize Every Shop Floor Action

Kopperlink Operator transforms manual and semi automated lines into connected environments where operators can report, trigger and manage essential actions directly from an industrial screen. Kopperlink Operator connects operator stations and digitalizes all shop floor actions to ensure instant and reliable data feedback. Operators can easily declare start, stop, quantities or defects, which centralizes production information in real time. With intuitive screens and optional automation of repetitive steps, manual lines gain precision, responsiveness and overall performance.

Kopperlink Operator connects operator stations and digitalizes all shop floor actions to ensure instant and reliable data feedback. Operators can easily declare start, stop, quantities or defects, which centralizes production information in real time. With intuitive screens and optional automation of repetitive steps, manual lines gain precision, responsiveness and overall performance.

Key Benefits

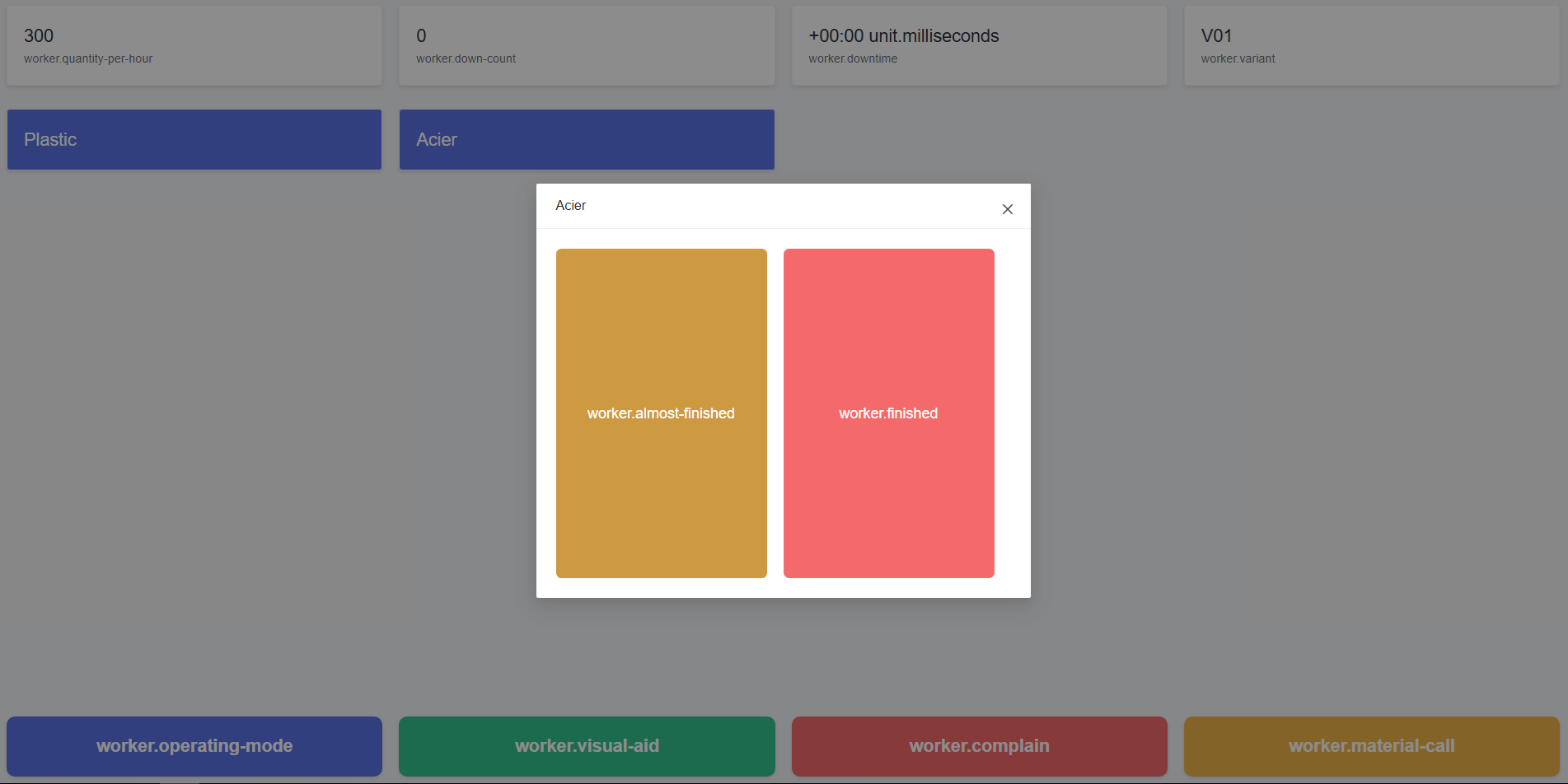

Fast and Simple Data Entry

Operators declare quantities, defects, stops or machine states directly from their station. The line centralizes all data in real time for immediate decision making.

Instant Reporting of Anomalies

Any incident, defect or support need can be signaled with one click. Relevant teams receive the information instantly and react faster.

Operator Interface Adapted to Every Line

Kopperlink Operator adapts to your processes. The interface can include start buttons, stop buttons, counting, validation or any other action required in daily production.

Automation of Repetitive or Critical Tasks

Depending on your needs, Kopperlink can trigger automatic actions such as quantity increments, state changes, step validation or custom sequences.

Unified Connection for All Manual Lines

Lines without automation become fully connected. Operator actions act as an automated interface, providing a complete and reliable view of production.

Observed Results

+18 %

Improvement in overall equipment efficiency thanks to richer and faster operator data.

–40 %

Decrease in human errors with dedicated buttons, guided screens and workflows adapted to your stations

–25 %

Reduction in intervention delays through instant detection and alerts sent directly from operator stations.

+30 %

Time savings for supervisors through smoother communication and instant visibility on operator actions.

Real Use Cases

Start and Stop Declaration

Operators report the beginning or end of each production phase, enabling accurate tracking of productive time and stops.

Real Time Increment of Produced Quantities

Each piece or batch can be counted with a dedicated button, ensuring reliable feedback for calculating efficiency indicators.

Reporting a Defect or Quality Issue

A defect is declared directly from the operator interface. Quality teams can intervene immediately and prevent the issue from spreading.

Material, Maintenance or Support Calls from the Station

Operators send intervention requests quickly. Support teams react faster and reduce production slowdowns.

Custom Automated Task Creation

Kopperlink can add specific buttons or actions to match your process, such as step validation, state changes, setup sequences, automatic timestamps and more.

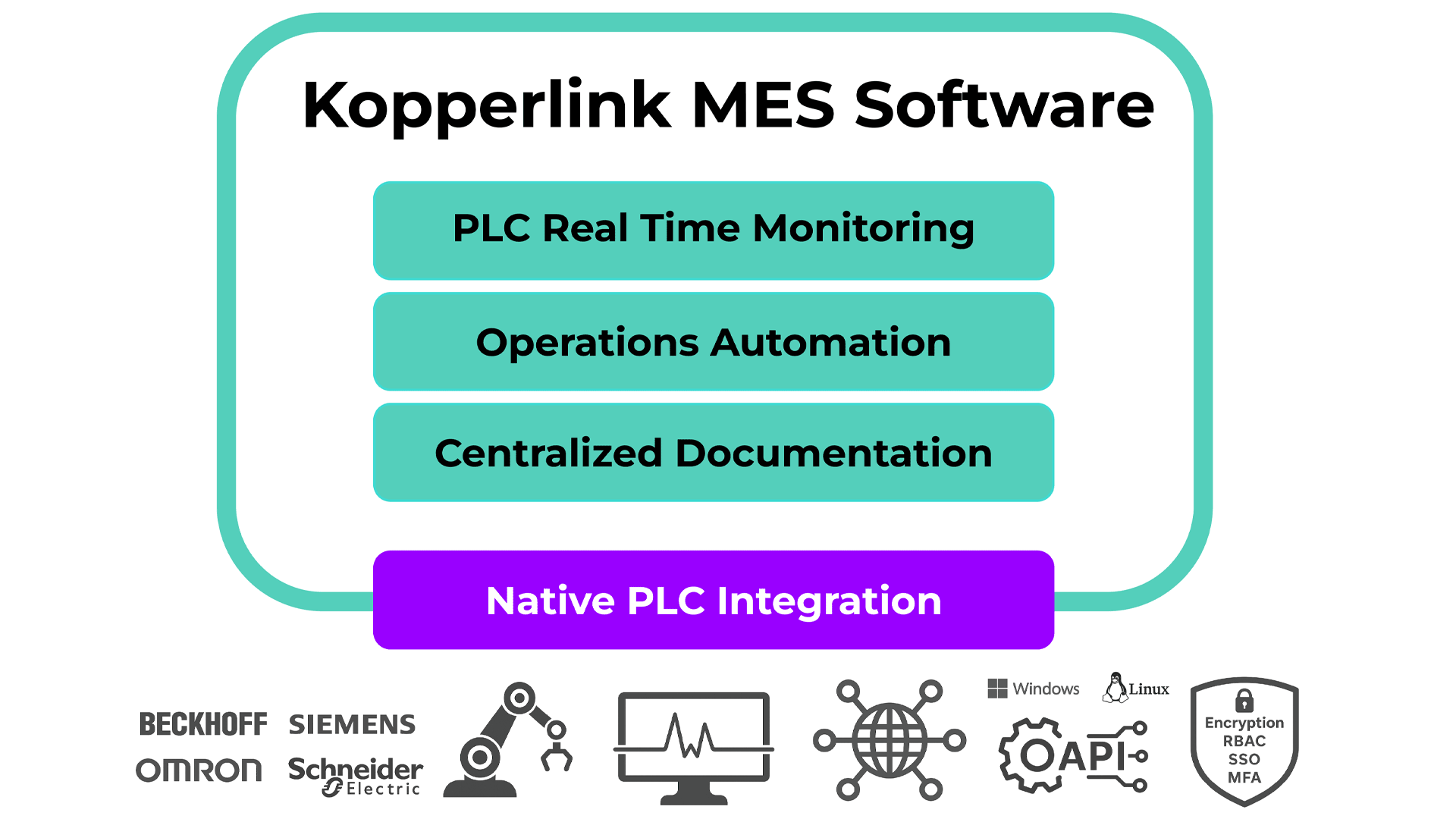

Seamless Integrations & Security

Kopperlink connects easily with your existing systems without rip and replace.

- ERP: SAP, Odoo, Oracle, Microsoft Dynamics

- SCADA & CMMS: Integrate maintenance and control systems

- PLCs: Compatible with Siemens, Schneider, and more

- Open API: Flexible connections for custom workflows

- Security: MFA, SSO, RBAC, and full data encryption

Unify machines, operators, and data in one secure platform.

Full deployment in less than a week.

Simple interface, easy to use.

Suitable for both small and large factories.

Works in all industrial sectors.

Modular platform, use only what you need.