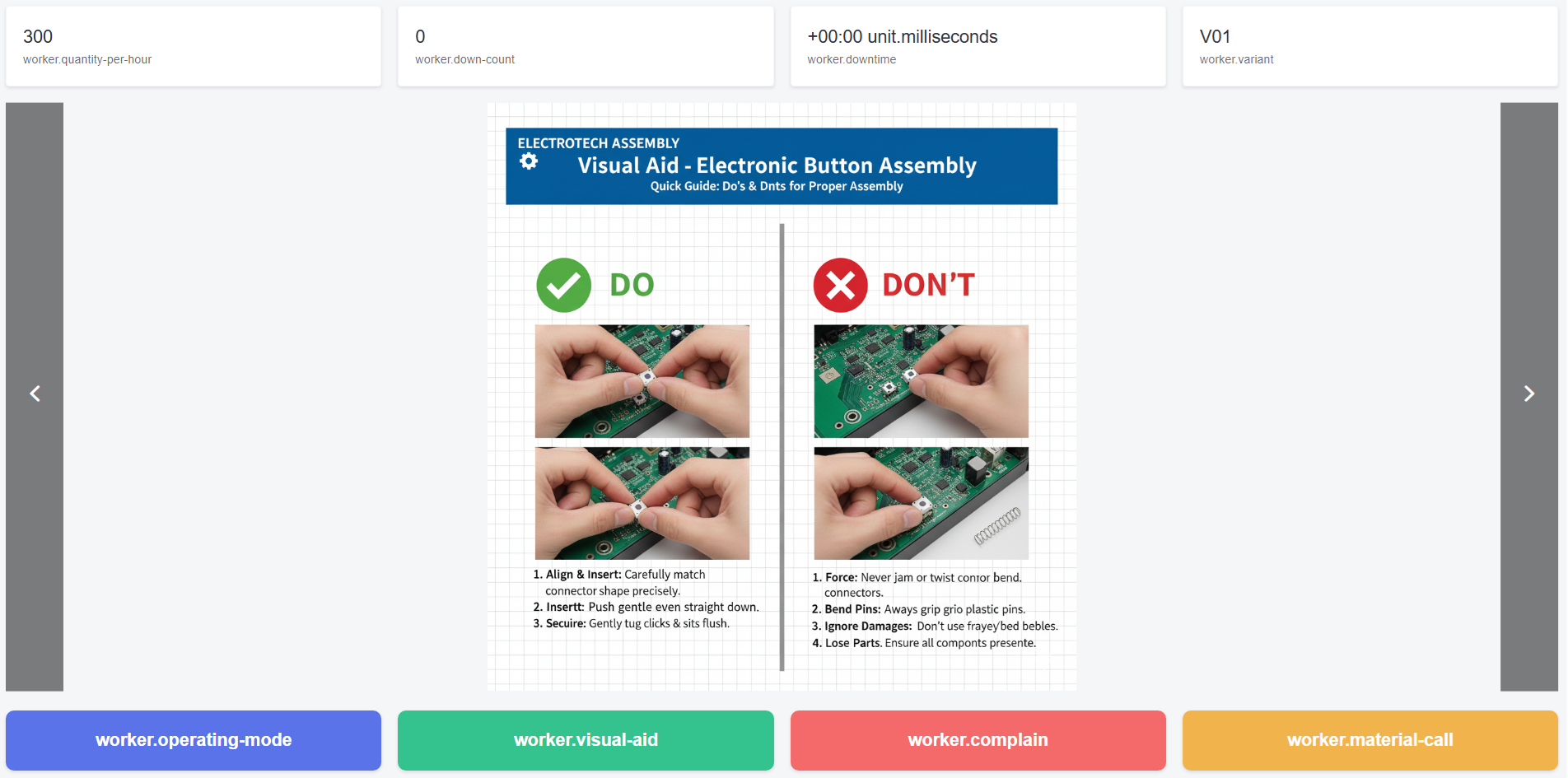

The Right Instruction at the Right Moment on Every Station

With Kopperlink View, teams access reliable and up to date documents instantly, improving productivity, quality and operational consistency.

Kopperlink View centralizes all instructions and procedures to ensure every operator always follows the correct version. Instant access to documents reduces errors, speeds up execution and unifies standards across teams. With version control, access management and immediate updates, production lines gain stability and full compliance. Fast to deploy and simple to use, View strengthens quality and operational performance.

Key Benefits

Centralized and Always Updated Documentation

All work instructions, procedures and quality sheets are available in one place. Operators access the correct version instantly, which reduces errors and improves execution

Immediate Reduction of Operator Errors

Standardized documents and automatic updates ensure a uniform application of standards. Errors caused by paper documents, outdated versions or interpretation issues disappear.

More Stable and Better Executed Production

tability and eliminate variations between shifts. Teams maintain a steady and well controlled production flow.

Stronger Compliance and Easier Audits

Full version control, complete modification history and controlled access. Obsolete documents no longer exist and audits become faster, more reliable and free of documentation non conformity.

Faster Operator Skill Development

New operators learn more quickly with visual guides and instant access to procedures. Training becomes shorter, more effective and more autonomous.

Observed Results

+21 %

Productivity improvement driven by instant access to information.

–15 %

Reduction in scrap and production errors due to standardized instructions.

–100 %

Total elimination of placement errors thanks to clear digital guides.

–50 %

Reduction in training time and orientation errors.

Real Use Cases

Suivi instantané de l’état de la ligne

Kopperlink réunit en un seul écran la performance, les arrêts, les appels matière et la progression horaire. Cette vue consolidée permet de détecter immédiatement tout écart et d'agir plus vite, ce qui améliore la stabilité de la ligne et réduit les pertes liées aux retards d’intervention.

Analyse rapide des temps d’arrêt

La répartition des arrêts par poste met instantanément en évidence les stations les plus pénalisantes. Les équipes peuvent cibler les interventions, corriger les causes récurrentes et améliorer la disponibilité de la ligne, tout en réduisant le temps nécessaire à l’analyse.

Détection automatique du poste goulot

Le poste goulot est identifié en temps réel, facilitant la résolution immédiate des contraintes qui ralentissent la production. En parallèle, les appels matière visibles sur le même écran évitent les ruptures de composants, garantissant un flux continu et mieux équilibré.

Pilotage précis du réalisé vs objectif

Le suivi en temps réel du réalisé, du cumul et de l’écart à l’objectif permet de corriger rapidement une dérive. Les superviseurs ajustent les ressources au bon moment, sécurisent la cadence et augmentent les chances d’atteindre les volumes journaliers.

Gestion digitalisée des Ordres de Fabrication

Les OF sont créés dans l’interface ou synchronisés automatiquement via l’API ERP. La planification offre une vision claire des objectifs, shifts et lignes, avec un suivi complet jusqu’à la clôture. Résultat : moins d’erreurs, davantage de traçabilité et une organisation de production plus fluide.

Consistent Application of Standards Across All Lines

Operators always follow the correct instruction, eliminating differences between teams and shifts. Quality becomes consistent, production flows more smoothly and deviations become rare.

Faster Changeovers and Settings Adjustments

Setup steps are visual and detailed, helping teams execute changeovers more quickly. This results in fewer errors, fewer stops and better machine availability.

Reduction of Quality Non Conformities

Critical procedures are always updated and available directly at the workstation. Controls and audits rely on reliable documents, removing issues caused by paper or outdated versions.

Instant Support for Industrial Engineering and Methods Teams

When a new version is published, it appears instantly on all relevant stations. No paper distribution, no delays, no conflicting documents.

Greater Operator Autonomy and Less Dependency on Supervisors

Operators find answers directly in clear, accessible instructions. Supervisors can focus on managing production rather than repeating explanations.

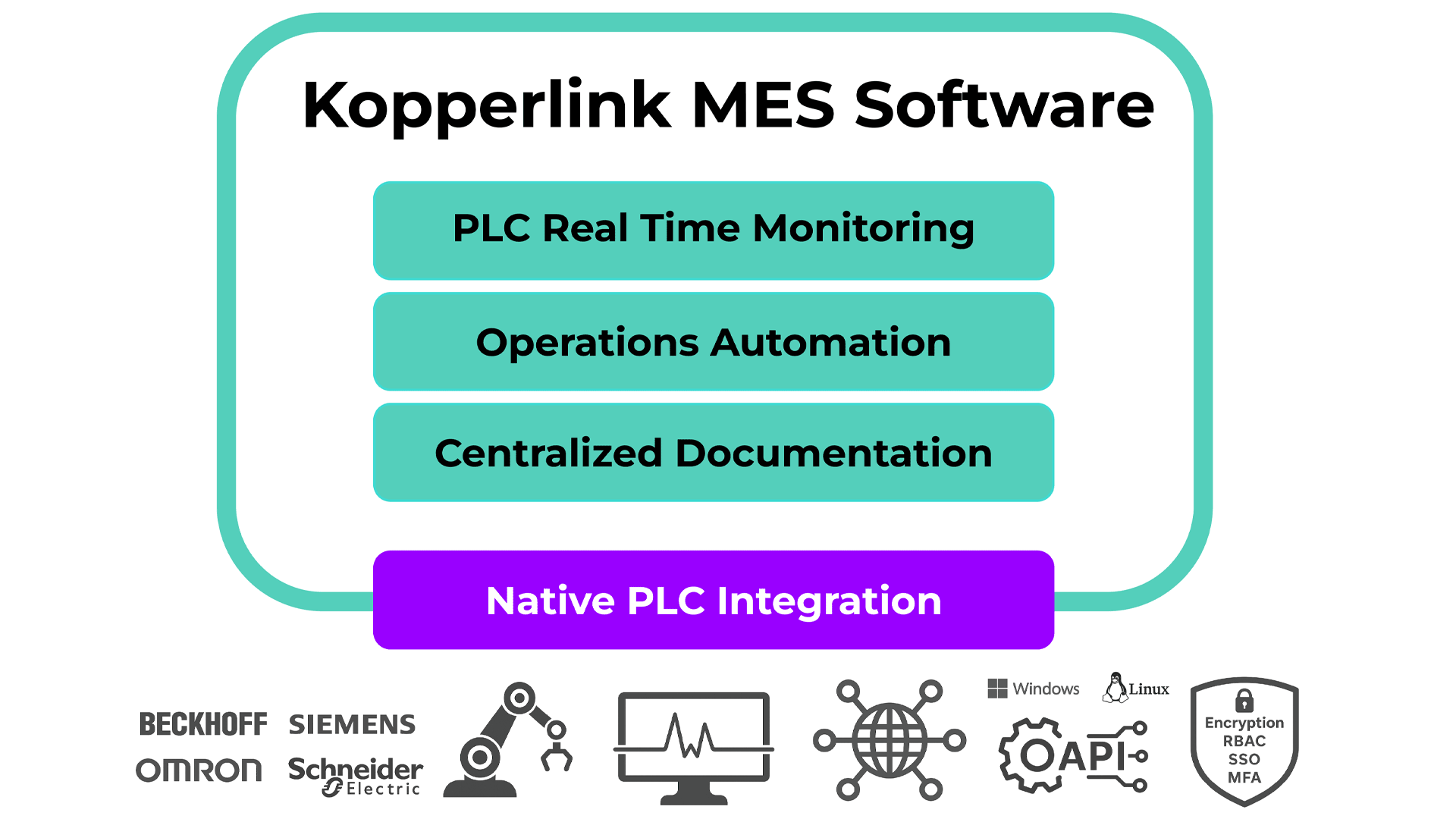

Seamless Integrations & Security

Kopperlink connects easily with your existing systems without rip and replace.

- ERP: SAP, Odoo, Oracle, Microsoft Dynamics

- SCADA & CMMS: Integrate maintenance and control systems

- PLCs: Compatible with Siemens, Schneider, and more

- Open API: Flexible connections for custom workflows

- Security: MFA, SSO, RBAC, and full data encryption

Unify machines, operators, and data in one secure platform.

Full deployment in less than a week.

Simple interface, easy to use.

Suitable for both small and large factories.

Works in all industrial sectors.

Modular platform, use only what you need.